Wet cast concrete production

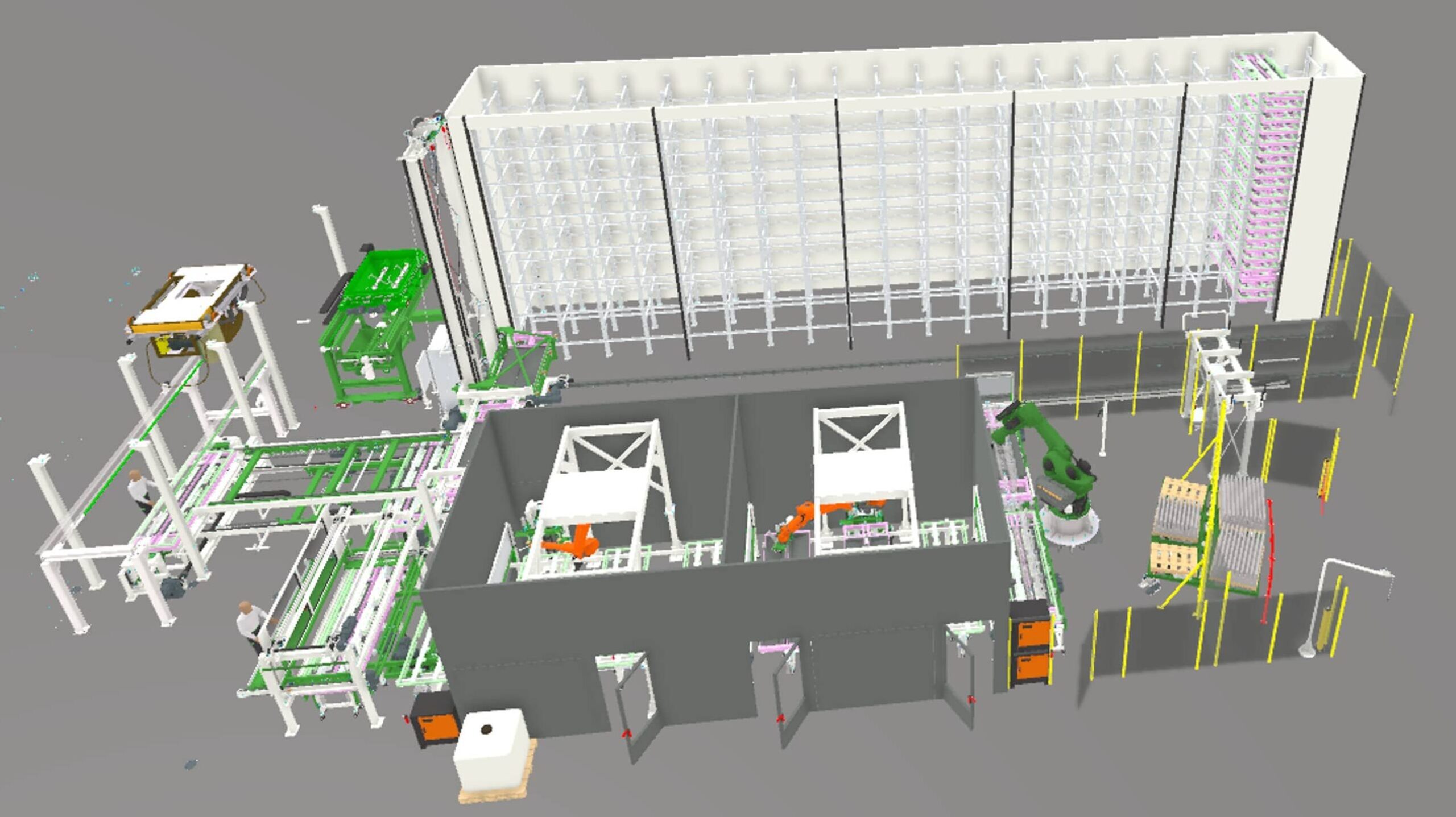

Concrete production lines with carousel and stacker crane

ALFI Technologies develops carousel production lines that meet the specific needs of concrete industry players. These lines guarantee constant quality production, high yields and optimum safety for operators.

These automated or semi-automated solutions support all stages of production from the preparation of concrete and mold filling.

In the case of elements with complex design, the custom made molds developed by CHAUDRONNERIE Savoyarde can incorporate automatic locking and unlocking and a coupling/uncoupling system of the two mold parts.

Our different production lines for wet cast concrete

Carousel for bulky concrete products

A production line with a carousel for the manufacture of bulky concrete products such as :

This carousel line can be easily adapted to your production sites and requires only 3 operators to operate. It also offers a perfect geometry of the manufactured elements.

Production rate: 1 mold every 2.5 minutes.

Storage capacity in racks:530 moulds of 2800kg max.

The production line integrates :

- A robotized lubrication system

- Demolding on pallets

- Inkjet marking of products

- Exit by shuttle outside the building

Carousel for flat concrete products

A production line with a carousel for the manufacture of flat concrete products such as :

This concrete production line with carousel requires only 3 operators to ensure its operation. It allows a perfect geometry of the manufactured elements as well as an irreproachable aspect of the visible face of products.

Production rate: 1 mold every 2 minutes.

Storage capacity in racks:420 moulds of 1500kg max.

The production line integrates :

- A robotized lubrication system

- A robotized mould brushing system

- Demoulding on pallets

- Inkjet marking of products

1 demoulding robot

Advantages of our west cast concrete solutions

Quick Return On Investment

Solutions developed by the company enable regular productions at high speed and with steady quality.

Modularity

These production lines are designed to follow the developement of companies, from the simplest to the most automated with very few manual workstations.

Versatility

The equipement allows the production of various types of items on the same line.

Manufacture of concrete street furniture

Resistant, maintenance-free and with various design, the concrete environmental products have evolved to meet new needs in terms of housing construction, decoration, urban planning and public area. The use of soft concrete during their production allows a high quality finish and aspect.

ALFI Technologies uses its unique expertise to offer turnkey installations for the production of vibrated and reinforced concrete environmental products.